More Productivity in Pandemic

Program: Exelerate HS-I, Evaporator cleaning

Insight

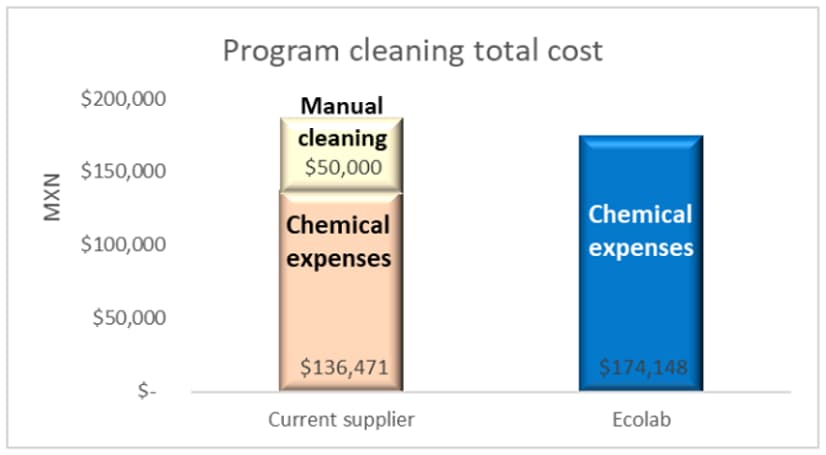

In the middle of last year and during the most intense months of the pandemic, our team was able to help a dairy plant to significantly improve its cleaning processes, which represents a greater time available to produce and a considerable decrease in the chemical use expense.

Challenges

1. Reduce the number of clogged fluxes

2. Final product out of parameters (whey)

3. Impact on effluent

4. Excessive spending on chemical program without expected results

Innovation

There was no standardized recipe, so we proposed a new recipe with formulated products (previously raw material was used). The formulated products allowed faster and more effective cleanings, reducing pre-washes and the number of inspections to verify cleanliness, which translated into more time to produce and less waste on chemicals. Training and follow-up were offered to all operators so they can apply the cleaning program correctly.

Additional Data