FillerTEK™ technology

Engineered Filler

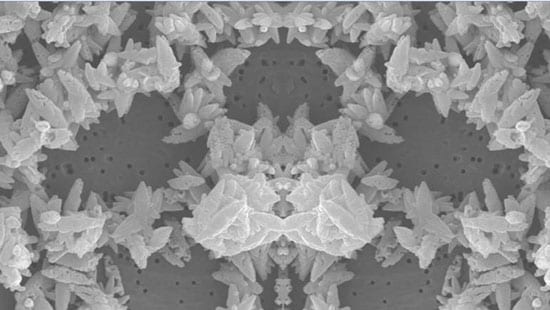

Nalco Water's FillerTEK technology combines several aspects of wet-end chemistry and filler pre-flocculation to make higher filler content achievable. FillerTEK technology is based on increasing the particle size of the filler through a unique method of pre-flocculation, with the net outcome being reduced interference of the filler with fiber-fiber bonding. The filler treatment is carried out on-site with a mill’s existing filler slurry.

FillerTEK technology is an ideal fit for paper producers utilizing precipitated or ground calcium carbonate (PCC or GCC), or a blend of the two carbonates as their filler source. Through utilizing the technology, paper producers can expect to achieve a high Return on Investment (ROI). Benefits have been identified in several areas including:

- Reducing fiber cost by 5%

- Maintaining strength properties

- Decreased steam usage at higher filler loadings